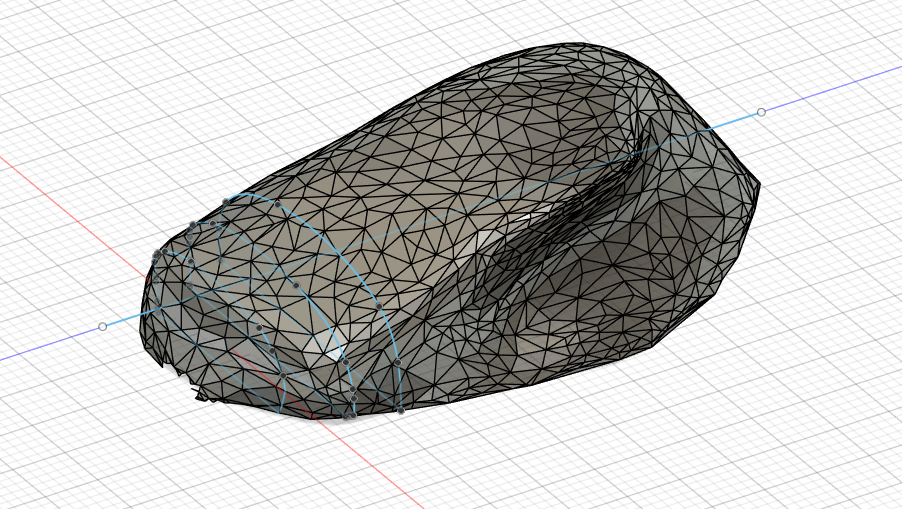

The mouse features a unique dual-shell architecture that separates interaction and sensing systems for improved performance and reliability.

The outer shell houses nine high-strength vibration motors distributed throughout the body of the mouse, along with a custom PCB responsible for user interaction features such as left click, right click, and the scroll wheel. This PCB also includes dedicated motor drivers for each vibration motor, with communication handled via the I²C interface.